As Harvard Business Review noted in its ‘An ESG Reckoning Is Coming’ article, ESG management is one of the top priorities for companies in 2021. ESG (an acronym for Environment, Social, and Governance) is a factor that determines a company's non-financial performance. The importance of ESG management has increased significantly for corporate sustainability management. Samsung Display has been carrying out various activities for the global environment in the display production process in accordance with the management principle that values the environment, safety, and health.

To produce eco-friendly products, Samsung Display reduced carbon, reused water, increased energy efficiency, and reduced warming components. As a result, the company received the 'foldable OLED environmental labeling certification' from the Korea Environmental Industry and Technology Institute last year and the 'Waste Landfill Zero Platinum' rating from UL, the global safety science company.

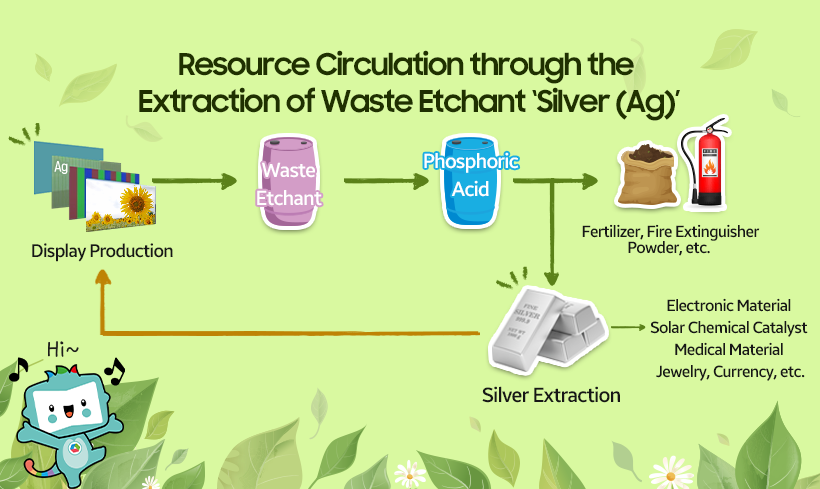

In addition, Samsung Display has recently succeeded in recycling resources and creating added value through innovative ESG activities for the environment. The company recently succeeded in developing technology that extracts and recycles silver from chemical waste (etchant) used to etch the surface of display panels. This article will introduce Samsung Display's ESG activities that go beyond resource-saving efforts to raise the level of environmental protection.

Silver in Display Waste?

Last year, Samsung Display launched the ‘Waste Etchant Recycling Project’ in June to protect the environment and recycle resources.

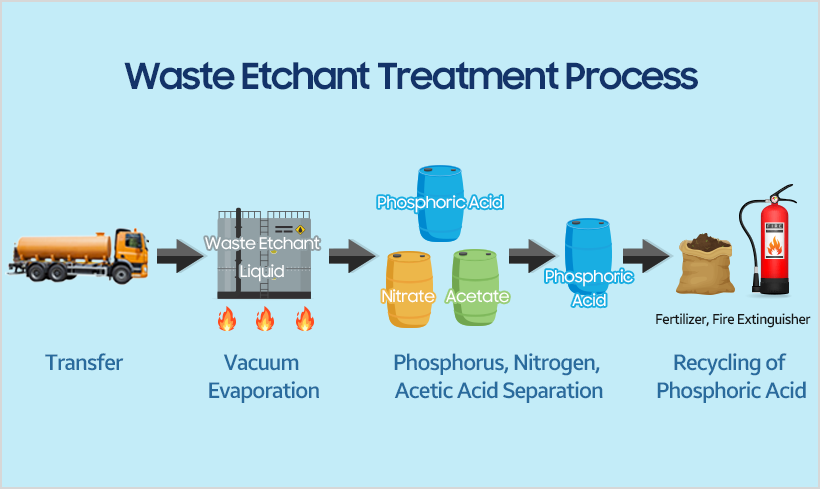

An etchant is a chemical liquid that thins the display surface by scraping it off. It is a material often used in the display production process. Until now, waste products were purchased and collected by companies specialized in waste and then refined into acetic acid, nitric acid, and phosphoric acid. And the refined acid has been reused as fertilizer or powder fire extinguisher.

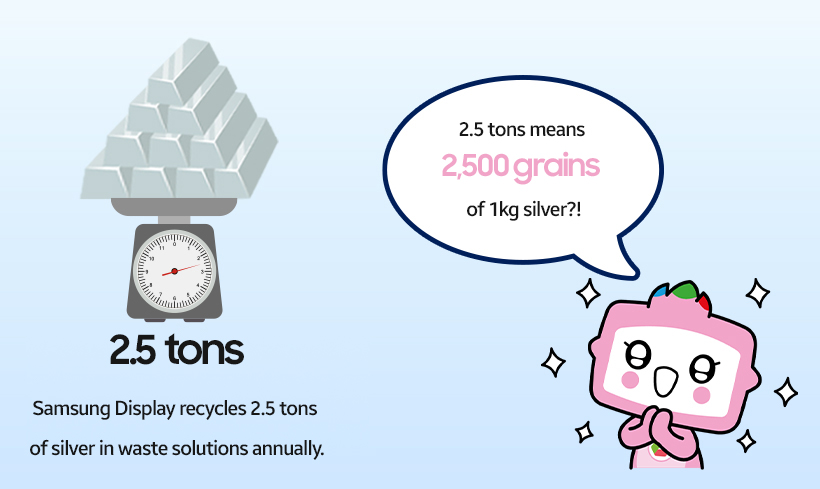

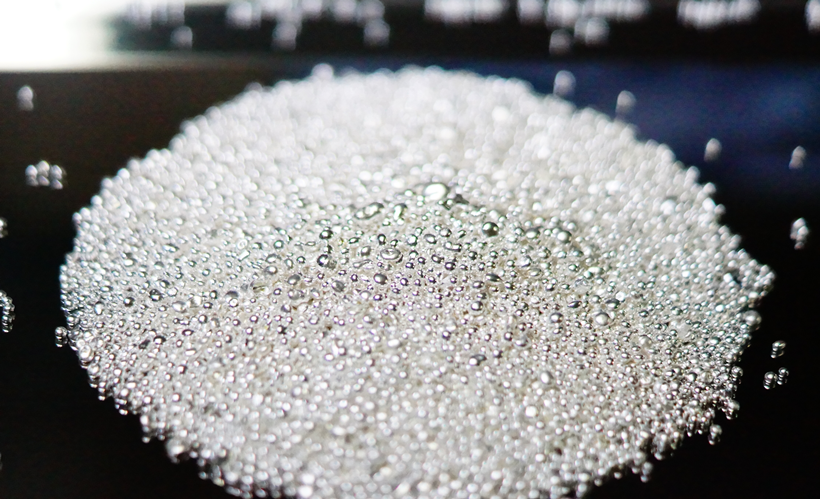

With tons of etchant waste generated, Samsung Display is consistently looking for ways to help save the environment and reduce costs by recycling. In the process, the company discovered that ‘Ag,’ commonly known as ‘silver,’ was present in etchant solutions. Samsung Display found that 1 ton of waste etchant contains about 300 grams of silver. Samsung Display recycles 2.5 tons of silver in waste solutions annually.

Imagine salt water: Salt exists in saltwater, but the particles are dissolved, making it difficult to separate from water. Similarly, silver produced from waste etchant is not metal, but the form of ions (Ag+), so they cannot be used immediately.

Modern-day alchemy of extracting ‘silver’ from waste etchants!

In general, when the waste etchant is purified, nitrate is evaporated, and heavy elements such as Ag are collected in phosphoric acid. However, since it is very difficult to extract ionic silver in a metallic form, there was a clear need to find an easier, cheaper alternative.

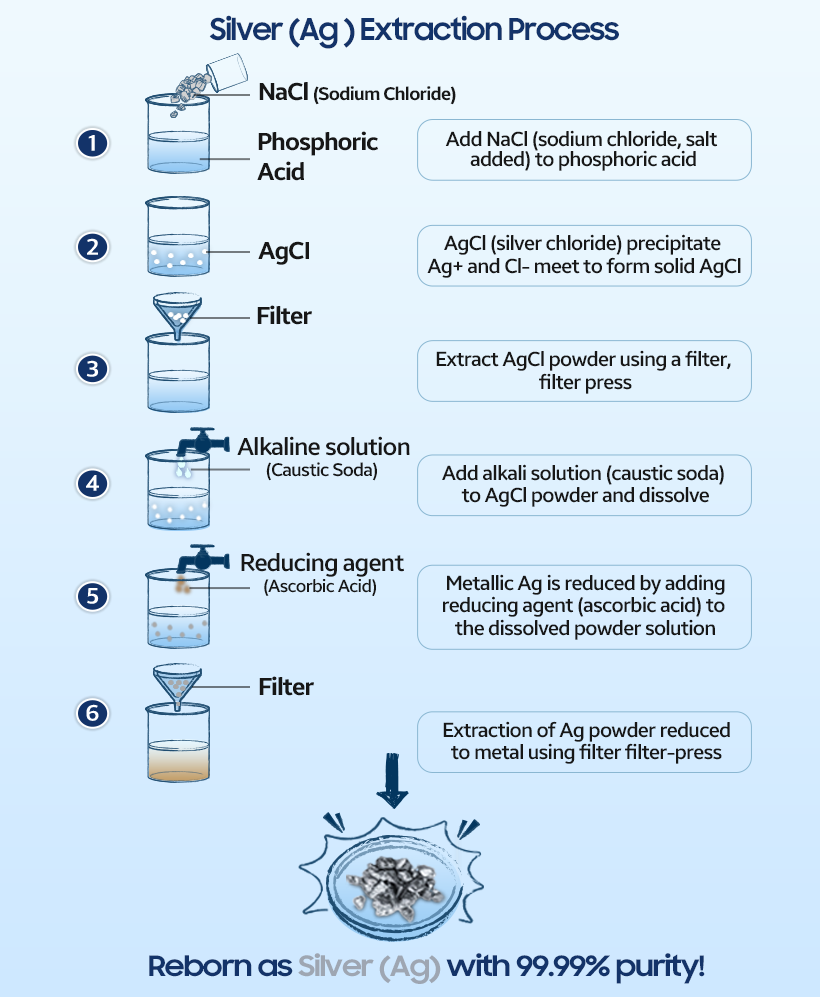

Although extracting metals from phosphoric acid was theoretically understood, there were issues during the actual extraction processes. Side effects such as corrosion of equipment or contamination of phosphoric acid took place in the process of causing a chemical reaction for extraction. However, Samsung Display was able to develop an optimized extraction material input and treatment technology! Extracting high-purity silver while minimizing side effects became a tangible outcome.

In summary, silver extraction occurs when Cl– ions are added to Ag+ ions in phosphoric acid to make AgCl in powder form, and then a reducing agent is added to remove Cl, leaving the only Ag in pure metal form. Silver, which used to melt in phosphoric acid and disappear in the original process, is now salvaged in its highly sought-after form.

Recycled Silver for Resource Circulation

Silver has been considered a precious element for 6000 years. Due to its reflective properties, it is commonly used to make mirrors. For its antibacterial properties, silver is also used to produce dishes and sterilizers. Its high electrical conductivity is well known within the electronics industry and has a wide range of applications, such as being used as a solar energy material for eco-friendly products.

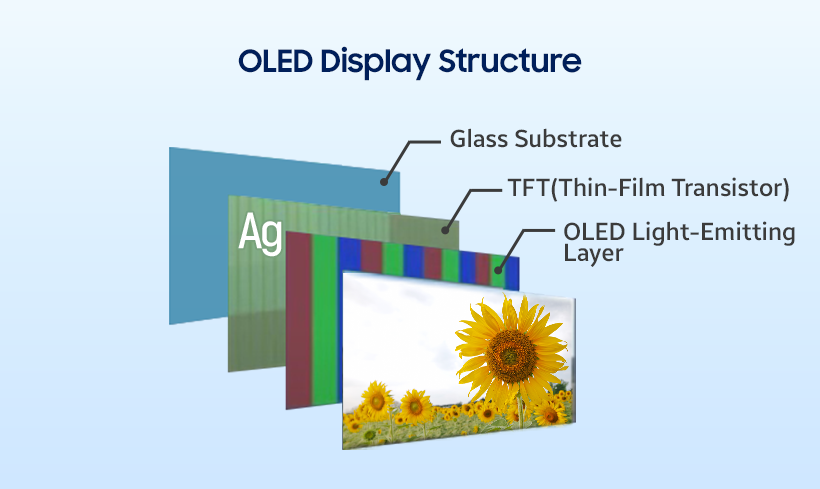

Silver (Ag) is also used as an important material for OLED display panels. Since OLED display works under the method in which organic materials emit light independently, it not only has excellent picture quality, but also has relatively low power consumption compared to LCD displays.

To show bright and excellent image quality even with a low amount of power, OLED displays use micro-cavity*, and silver (Ag) is used as a reflective material. The whole discovery of recovering silver in waste etchant of the OLED display process took place during the process of thinning reflectors where parts of the silver component escaped. In the end, Samsung Display paved the way for resource circulation that can regenerate silver from waste and ultimately use them as materials in display production.

* a structure formed by reflecting faces on the two sides of a spacer layer

By recovering silver which originally evaporated during the process, Samsung Display not only created an additional value of approximately $1.3 million dollars (1.5 billion won), but also actively supported waste collection and refining companies with relevant technologies so that they could be used in the actual process sites. Through the ‘waste etchant recycling project’, Samsung Display was able to solve environmental problems, reduce the cost of waste disposal, and achieve win-win through technical support for business partners.

Samsung Display plans to consistently innovate how companies reuse not only waste etchants solutions but also other various wastes generated in the process. Its contributions to sustainability and preservation of the environment will continue as the company commits to providing ‘Display that goes beyond imagination.’