Thin Film Transistor (TFT) is an electronic circuit to control the brightness of pixels in a display. It is composed of several layers – Source/Drain, Gate, Active Layer – and is divided by the characters of TFT materials, such as LTPS, Oxide, a-Si, and etc. Amorphous silicon (a-Si) is one of the types of TFT materials.

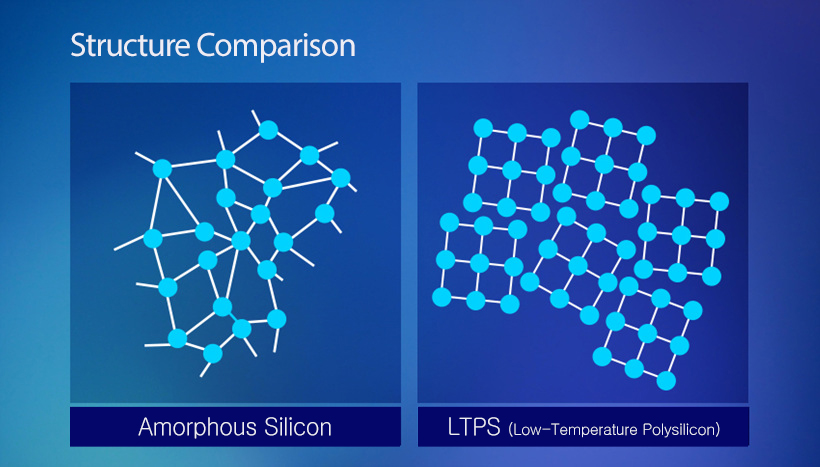

Usually, the atomic arrangement of solid has crystallized, and an amorphous means a state with a disordered arrangement of atoms. Therefore, amorphous silicon refers to silicon that doesn’t have a certain range order, rather forms a continuous random network.

In the early days, amorphous silicon is mainly used for LCD TFT because the manufacturing process of TFT using amorphous silicon was relatively simple and the yield rate was high. In addition, the advantage of uniform deposition on the panel enabled producing large-sized panels. In a nutshell, it was the optimal technology for saving manufacturing costs and producing in a stable.

TFT controls the brightness of each pixel on a screen by regulating the electric current. However, TFT using amorphous silicon have limitations in making electrons move quickly due to the disordered atomic arrangement of silicon.

If the electron mobility is low, the speed of signal transportation gets slower. It was not the matter for the early days of LCD panels, but it could lead to degenerate efficiency as the display structure become more complicated and image quality more high-resolution.

LTPS TFT was developed in order to improve this disadvantage. By crystallizing randomly ordered a-Si with a laser into polycrystalline silicon, which has a certain amount of order in the structure, LTPS TFT increases the electron mobility hundreds of times faster.

LTPS TFT is widely used in OLED backplanes for smartphones or laptops thanks to its applicability in high-resolution display panels, even though the manufacturing process is relatively complicated.