Photoresist (PR) is a light-sensitive material that changes its properties during the photolithography process, which forms intricately detailed circuits on thin-film transistors (TFT) used in the display industry.

Imagine a material that either hardens or melts when exposed to light; photoresist, depending on the type, shifts its chemical properties. By leveraging this chemical transformation, fine circuit patterns are fabricated by washing away the unnecessary parts during the photoresist process, like engraving the plates for printmaking industries, also known as photolithography.

The process begins with photoresist being lightly coated on top of the TFT substrate during the photolithography process, which is the key manufacturing process of TFT. Next, a photomask is placed on top of the photoresist as a way to differentiate the circuit parts from the rest. Based on whether it was exposed to the light or not, a part of photoresist becomes malleable, and one part is removed during the development process depending on the difference in solubility between the two regions. Any remnants left are taken out during the etching process while the substrate stays intact underneath the cut out layer of hardened photoresist. Lastly, the rest of photoresist is stripped off, leaving behind the final parts used for TFT circuits.

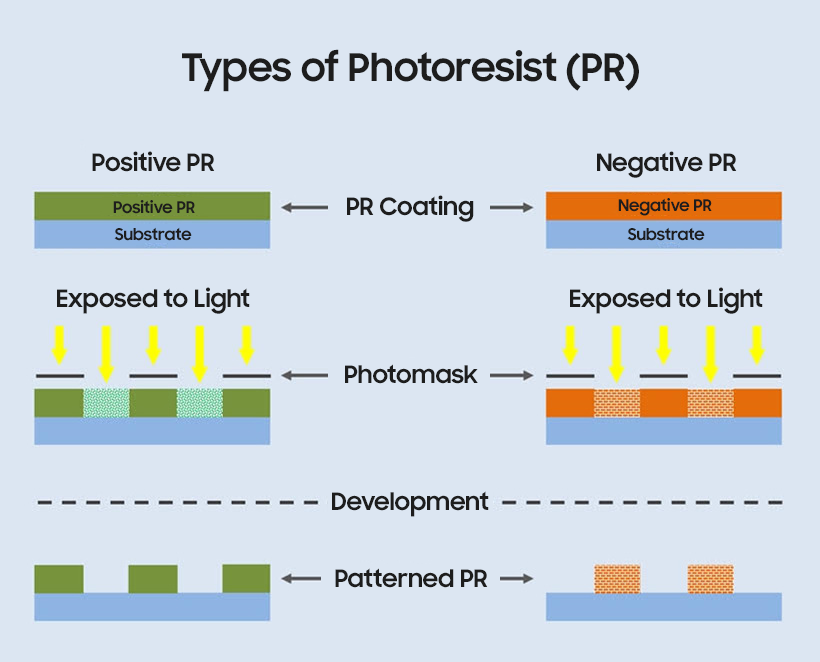

There are two types of photoresist: Positive and negative resist. Since positive resists that are exposed to light are left soluble, while the light exposed negative resists remains on the surface and unexposed areas are removed by the developer solution, they are used selectively based on specific needs.

In essence, photoresist is one of the key materials needed in photolithography, which is a crucial process for determining the level of miniaturizing thin-film transistor (TFT) display circuits.