Indium tin oxide (ITO) is one of the key materials used in a display panel. A display reproduces images by controlling the brightness of its pixels through an electrical flow. Each pixel, therefore, requires an anode and a cathode for electrical conductivity. Not only does the material for the electrodes have to offer great electrical conductivity, but also offer transparency for light to pass through the display.

Mixing indium oxide(In2O3) and tin-oxide(SnO2) results in an oxygen vacancy that induces the movement of electrons and holes (absence of electrons), essentially electricity; this mixture is indium tin oxide. On top of the electrical conductivity, the ITO layer becomes transparent when made with thin layer and is therefore often referred to as a transparent conducting electrode (TCE).

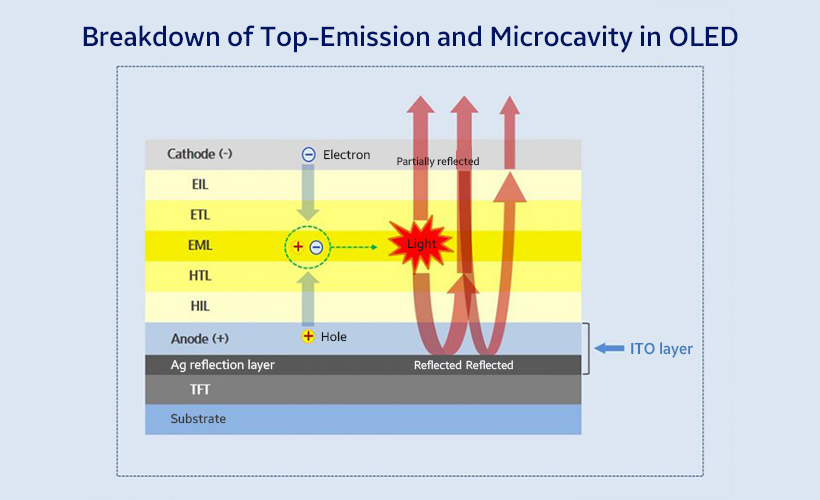

For LCDs, the ITO layer serves as an electrode that controls the light emitted from the backlight passing through the liquid crystals and ensures that the emitted light reaches our eyes. For OLEDs, the ITO layer largely serves two functions: In bottom-emission OLED(BE-OLED) displays, the layer functions similarly to the ITO layer in LCDs. However, in the top-emission OLED(BE-OLED) displays, the ITO layer ensures that the holes are seamlessly injected from the anode to the organic hole injection layer (HIL).

The reason why the ITO layer is used as the material for anodes is that it has the energy level suitable for the movement of holes. At the same time, the optical transparency of ITO allows for creating a structure called a ‘microcavity.’ In the context of displays, microcavity refers to a technology that leverages the property of light as waves (constructive interference) to dramatically enhance the intensity of light, thereby amplifying the luminous efficiency. Microcavity is realized by using the transparent ITO in the anode - enabling light to pass electrodes, reach the Ag (silver) layer and get reflected.