Quantum dots are tiny particles that are only a few nanometers in size*. One of the defining properties of quantum dots is the great adjustability of the electric and optical properties of the material as well as colors of the light it emits through slight tweaks in the particle size.

*A nanometer is one billionth of a meter

This is a great advantage that draws the attention of various industries. Using a matter that is bigger than 1 µm* requires the use of a different raw material when different properties are needed, but quantum dots eliminate the need to seek a new raw material as their properties can be modified by adjusting the size.

*Micrometer; one micrometer is one millionth of a meter

Research is being carried out to utilize quantum dots in various fields — examples include displays, where reproduction of natural colors is critical; solar cells, whose existing materials have clear limitations in optical conversion efficiency; and bioimaging, which requires a visible spectrum and near-infrared light that can be seen through biological tissues. While a tremendous amount of research is being done to customize quantum dots to the unique characteristics of each field, there is a common priority across all fields: Ensuring that the raw material for quantum dots is eco-friendly.

Cadmium Replacements in Place Due to its Health Hazard

The first quantum dots were derived from cadmium. The first quantum dots that were discovered in 1982 and the first successfully synthesized quantum dots in 1993 both used cadmium serving as their key raw material.

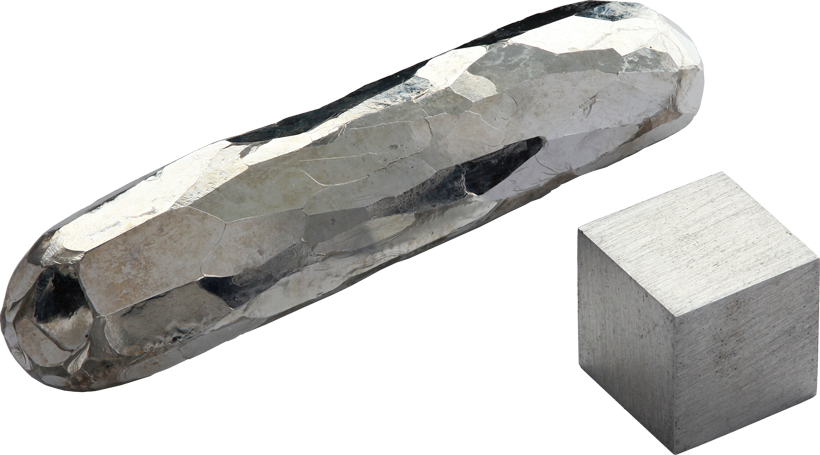

Cadmium is silver-white metal that is soft and malleable enough to be easily cut with a knife and offers great electrical conductivity. It can also mix well with other elements, making it conducive to create compounds with added benefits. Leveraging this characteristic of cadmium, artists mixed cadmium with sulfur compounds to create red and yellow pigments in the 1800s. In the 1930s, cadmium was used as protective coating for cars and aircrafts to prevent corrosion, and starting from the 1980s, it has been used to manufacture cathodes used in nickel-cadmium rechargeable batteries.

But cadmium poses a critical issue. It is toxic. Concerns have been consistently raised regarding the toxicity of cadmium over several decades. What brought the world’s attention to this hazardous nature of the element was itai-itai disease, cited as one of the four major pollution-related diseases in Japan. The disease was found mostly near the Jinzu River in Toyama Prefecture in Japan around the 1910s and is known to cause pain in the spine, hands and feet, and joints and increase the likelihood of bone fractures.

Mining waste containing cadmium, created through the process of smelting zinc in the mines, was leaked into the river in Toyama Prefecture, polluting the water for drinking and agriculture in the area and eventually causing itai-itai disease in the residents. At first, an endemic disease and malnutrition were suspected as possible causes of the disease, but in 1968, it was discovered that cadmium was the culprit.

In the 1970s, a series of studies were published suggesting that even the small amount of cadmium was hazardous to the human body even if it may not be concentrated enough to cause itai-itai disease. Exposure to cadmium causes inflammation, which leads to fever, respiratory disorders, and muscle pain, and long-term exposure to the metal can cause a severe disorder in the respiratory and renal systems. Cadmium is particularly dangerous as its chemical properties are similar to those of zinc, an essential component in the body, and can be easily absorbed into the body and bind with the enzymes in the system to cause kidney disorders.

Due to such risk, the International Agency for Research on Cancer (IARC) under the World Health Organization (WHO) has classified cadmium as ‘Group 1’ element for being carcinogenic to humans. The U.S. Environmental Protection Agency (EPA) has also classified cadmium as a Group B1, probable human carcinogen.

Most of the industries that used to rely on cadmium are now seeking ways to replace it with other materials. Nickel-cadmium rechargeable batteries that relied the most on cadmium are now being replaced by other forms of batteries such as nickel compounds, lithium-ion, and lithium-polymer batteries.

The same trend can be seen in quantum dots. Being in close contact with, or worse, inserted into the human body, displays and bioimaging technologies cannot use cadmium as their raw material. Quantum dot solar cells are not an exception either as they are being studied to be used in wearable and mobile devices. In 2013, the first quantum dot TV launched by Sony was discontinued within only a year after its release in the market, and it was reported that the low sales performance was predominantly attributed to the use of cadmium in the product.

According to Wan Ki Bae of the Department of Nanoengineering at Sungkyunkwan University, “Synthesis of Group 12 elements such as cadmium with Group 16 elements* is rarely used in the research on quantum dots. Most of the research is being done on the synthesis of elements from Groups 13 and 15**.”

*Quantum dots consisting of elements from Groups 2 and 6, or the II-VI quantum dots

**Quantum dots consisting of elements from Groups 3 and 5, or the III-V quantum dots