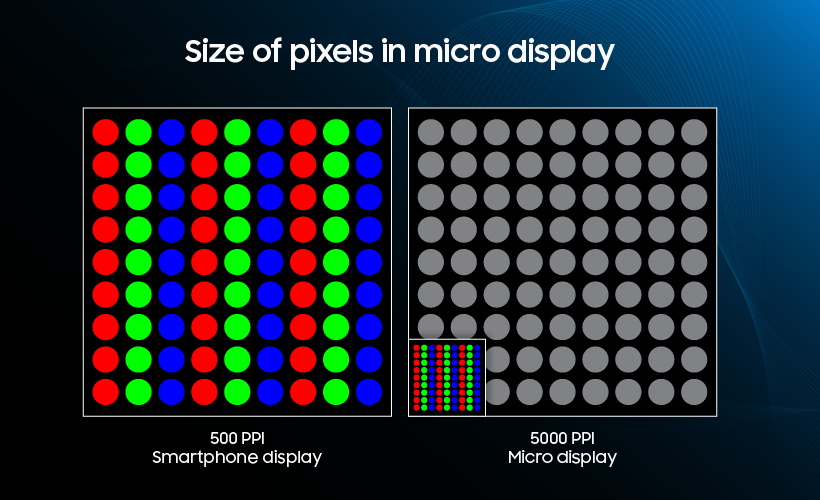

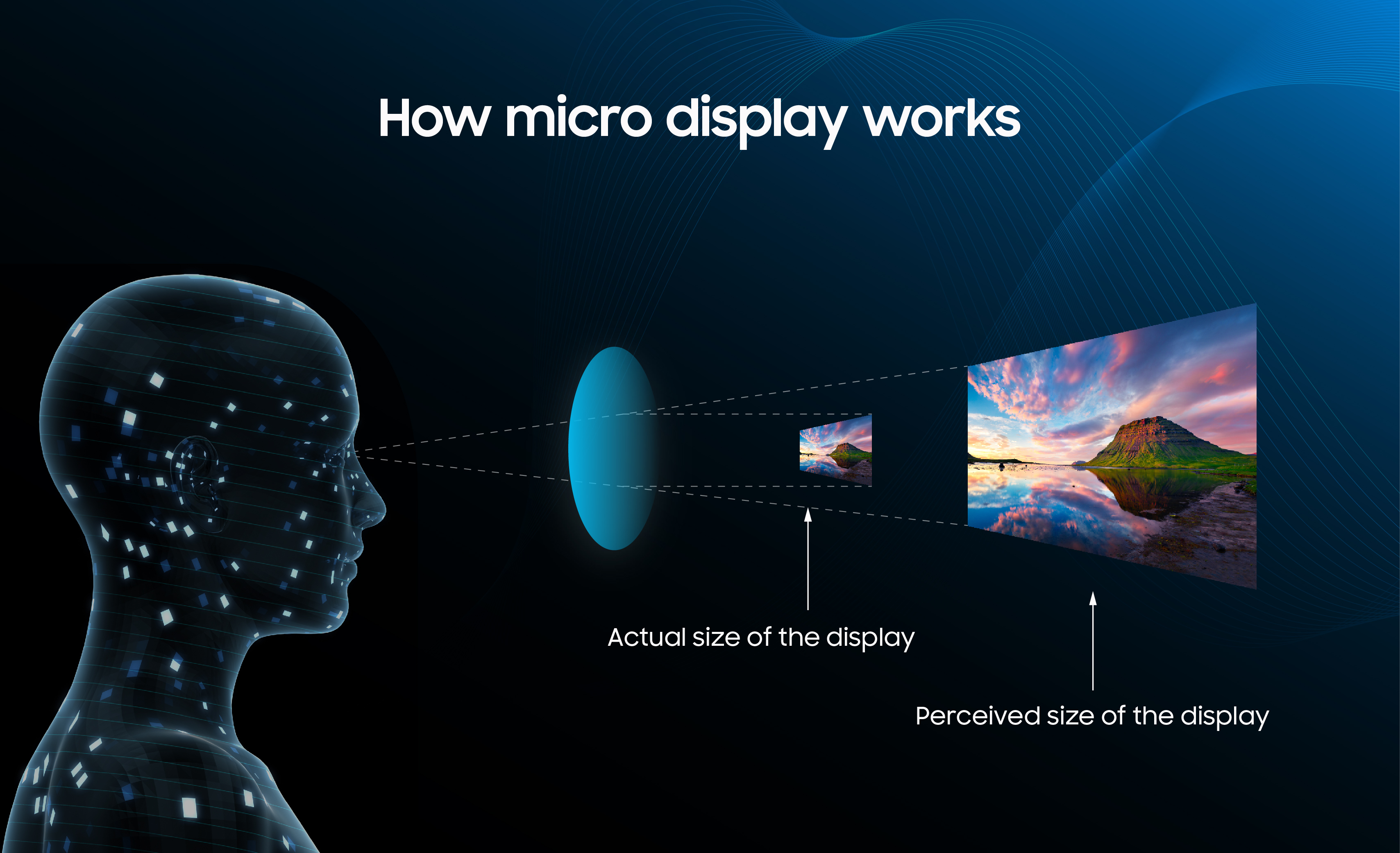

A micro display is a term for ultra-high-resolution displays with a dense pixel arrangement, often reaching thousands of pixels per inch (PPI) within a compact size of around one inch.

Despite their small dimensions, micro displays can create an image of a significantly large scale, establishing them as a key technology for virtual reality (VR), augmented reality (AR), and mixed reality (MR).

Most micro display technologies utilize silicon wafer substrates, akin to those found in semiconductor applications. Wafer substrates facilitate faster movement of electrons within circuits compared to the glass substrates used in traditional displays. Enhanced electron velocity improves the display's performance, reducing response time and resulting in a sharper image with less artifacts.

Heat treatment enhances the performance of silicon-based circuit boards by promoting homogeneity, facilitating a smoother movement of electrons as the temperature increases. In contrast, conventional glass substrates are vulnerable to temperatures exceeding 500°C. To address this limitation, silicon wafers are utilized, which undergo heat treatment at a higher temperature. Consequently, this technology is denoted in the form of [main technology name + on Silicon]. For example, a micro display combining OLED technology on silicon is referred to as [OLED on Silicon (OLEDoS)].

The three main types of micro displays include LCoS (Liquid Crystal on Silicon), which utilizes liquid crystals; OLEDoS (OLED on Silicon), employing OLEDs; and LEDoS (LED on Silicon), using LEDs.

LCoS, the oldest technology dating back to 1970, has found widespread use in beam projectors. This method involves projecting an external light source onto liquid crystals and reflectors, creating a substrate on a silicon wafer, and configuring an LCD on top. Its advantage lies in leveraging the existing LCD process.

OLEDoS involves coating OLEDs on a silicon wafer substrate. It can be categorized into white OLEDs using color filters (C/F) and RGB methods where subpixels emit individually. Unlike LCoS, OLEDs emit their own light, eliminating the need for an external light source. Both the substrate and OLEDs exhibit excellent response speeds, which is beneficial for achieving ultra-high-resolution screens.

LEDoS entails coating LEDs, which are inorganic devices, on a silicon wafer substrate. As a self-emitting technology, it boasts a high color reproduction rate and brightness (luminance) that surpasses OLEDoS.

As the XR (AR/VR/MR) industry expands, micro display technologies that enable its implementation are undergoing rapid research and development. Fierce competition among these technologies is driving innovation, and it is anticipated that applications will diversify into fields that align with the unique strengths of each technology.