A fine metal mask (FMM) is a metallic plate that deposits light-emitting organic materials to an accurate location on the substrate during the OLED display manufacturing process. As a metal mask with fine holes in it, a FMM induces the light-emitting organic material to pass the holes in the mask so that it is deposited onto the desired location on the substrate.

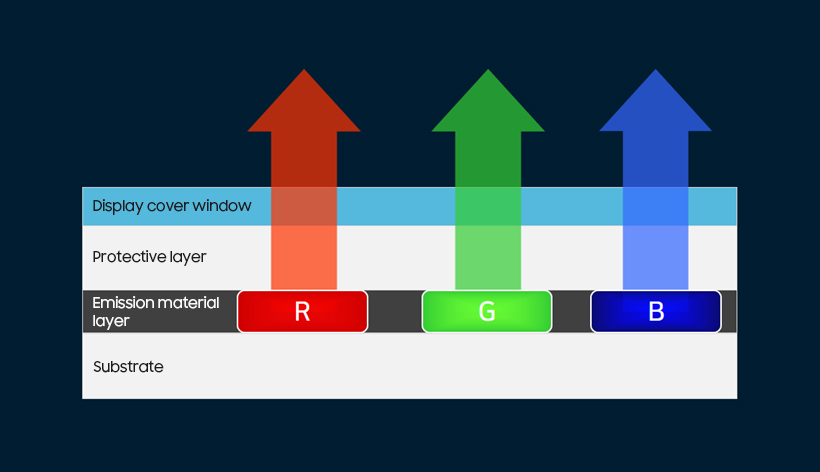

An OLED display expresses images through the assembly of pixels that consist of organic materials, and each pixel can independently emit different colors. The reason why a pixel can deliver a variety of colors is that it is composed of sub-pixels that emit three primary colors: Red, green, and blue. Sub-pixels are created through a process called evaporation. Evaporation refers to bonding a material thinly on the surface of a substrate. To deposit an organic material onto an OLED display substrate, the material is usually heated in a vacuum to be evaporated.

To ensure that the organic material for the sub-pixels is evaporated onto an accurate location, the evaporation process is conducted after the holes in the fine metal mask (FMM) are accurately aligned with each of the three primary colors. To prevent the colors from mixing with each other during the evaporation process, a different FMM is used for each color of the sub-pixel. Once the evaporation process for the sub-pixels is complete, the emission material layer (EML) of the OLED display is created, after which application of the complementary layer for light emission and encapsulation process is carried out.