A clean room is a controlled environment within fab facilities that produce displays or semiconductors. Various factors (ex: temperature, humidity, air current/pressure) along with air contamination are all maintained under strict standards. Even the tiniest particle can cause damage on ultra-fine circuits and thin film layers for displays, which is why a clean room is required to ensure elimination of atmospheric contaminants.

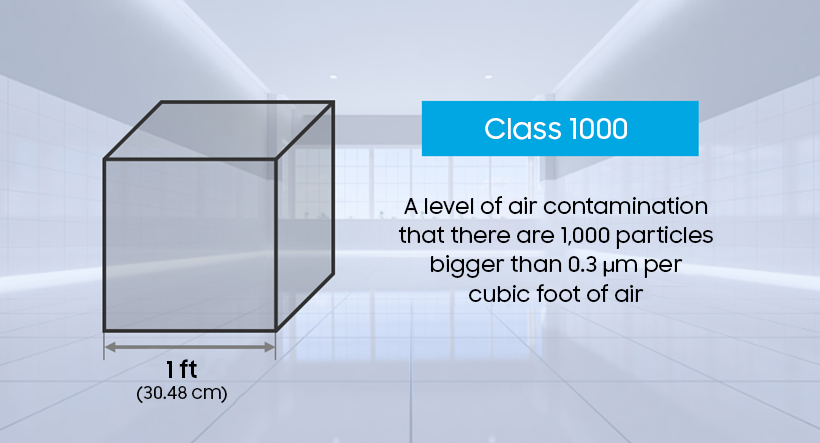

Clean room classifications are divided into ‘classes’ based on the size and numbers of particles in the air. In the display industry, a class refers to the number of 0.3 micron (µm) sized fine dust/particle per cubic feet (f³): It’s eight times stricter than the standard for measuring major air pollutant of PM2.5 (a particle with diameter less than or equal to 2.5 µm). For example, ‘Class 1000*’ clean room denotes that there are 1,000 particles bigger than 0.3 µm per cubic foot of air. Most of the OLED display processes in the fabs, such as thin film transistors (TFT) and encapsulation, all take place in a ‘Class 1000’ clean room, which comes with a level of cleanliness undeniably comparable to the Class 3,000,000 environment typical air condition.

*US FED STD 209E standard, equivalent to ISO 6

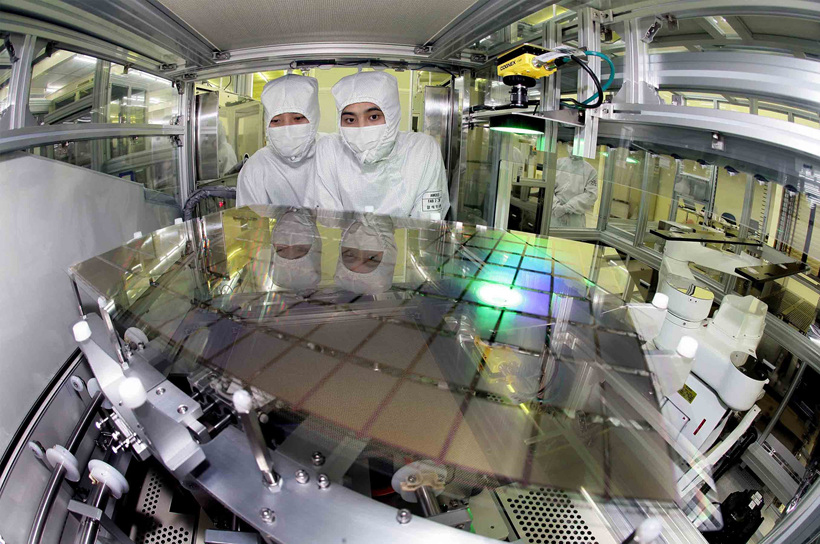

Dust gets generated within the clean room as a lot of workers and production facilities moves around frequently. To control airborne contaminants 24/7, the clean room consists of multiple working devices. The ceiling mounted with ultra-fine fan filter units and filtration system underneath the floor help maintain a high level of air cleanliness; all workers are required to wear “bunny suits'' and pass through air showers before entering the clean room. This clean room apparel not only reduces particle contamination (ex: hair, dust) but also prevents electrostatic discharge (ESD) that can affect display circuits. As display production involves ultra-fine processing, clean room is yet another measure taken to ensure exceptional quality by creating a dust-free environment.